Internal combustion forklift

Your one Stop Material Handling Solution Provider: FORKFOCUS CHINA.

Working with us, you will receive:

- Professional pre-consultation.

- Working out the most practical solution for you.

- Fastest delivery (15 days for emergency order).

- Most cost-effective container shipping.

- Documents for custom clearance,.

- After sales.

- Maintanance guidance.

- One stop service since you become our customer.

- Indurstry report sharing.

- Market research for your specific business for free anytime.

- Any other reasonable request within our capacity is available for free.

Check out fork focus forklift performance

Internal Combustion Forklift Overview

It’s not easy to introduce every aspect of internal combustion forklift. We’d like to get into below aspect to let you have a general understanding for that. FORK FOCUS, tries to be your most trustable forklift supplier in china!

Such kind of diesel forklift is widely used in various kinds of working conditions.

We have 1.5T to 3.5T for this category and almost the same design just different dimensions.

We have a close business cooperation with most professional forklift manufactures

like hangcha/HC with most competitive price than any others except HC itself!

Welcome to inquire and compare the price!

For this small model diesel forklift, we have engines are available with:

- Isuzu C24O engine;

- Yanmar 4TNE 92/98 engine;

- Mitsubishi s4s engine;

- Chinese xinchai engine.

When asking for an inquiry, there are some technical words you should know or understand. This is the necessory process to know what kind of forklift you really need.

Forklift technical words you should know:

What's Rated Load capacity

The rated load capacity is the forklift capacity to carry how much tonnage of cargo at or below the rated load center.

When the actual load center exceeds the specified load center distance, the lifting weight will be reduced accordingly due to the limitation of the longitudinal stability of the forklift.

What's Load center. ( C)

It’s about the distance the horizontal distance from the center of cargo to the front wall of the vertical section of the fork. It’s usually expressed in millimeters.

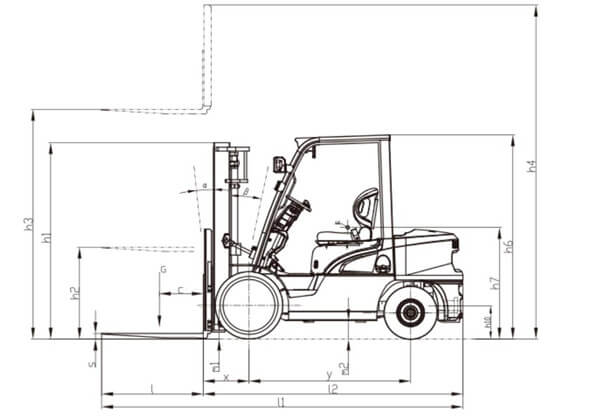

For forklifts of 1-4 tons, the specified load center is 500mm. See C in below picture.

The maximum lifting height. (h3)

On a flat and solid ground, when the forklift is fully loaded and the cargo is raised to the highest position, the vertical distance between the upper surface of the horizontal section of the fork and the horizontal ground where the forklift is located.

The inclination angle of the mast. (α°/β°)

It’s about the maximum inclination angle of the mast forward or backward relative to its vertical position when forklift was placed on a flat and solid ground under no-load condition.

The forward inclination angle is to carry and unload the goods.

The backward inclination angle is to prevent the goods from slipping off the forks when the forklift is running.

Generally, the forward angle is 3-6°, and the backward angle is 10-12°.

What's Maximum lifting speed.

It’s about the maximum lifting speed of the goods when the forklift is fully loaded.

It’s expressed in meters per minute.

Increasing the maximum lifting speed can improve operation efficiency.

But if the lifting speed is too fast, it’s prone to cause cargo damage or machine damage.

At present, the maximum lifting speed of chinese forklifts has been increased to 20m/min at most.

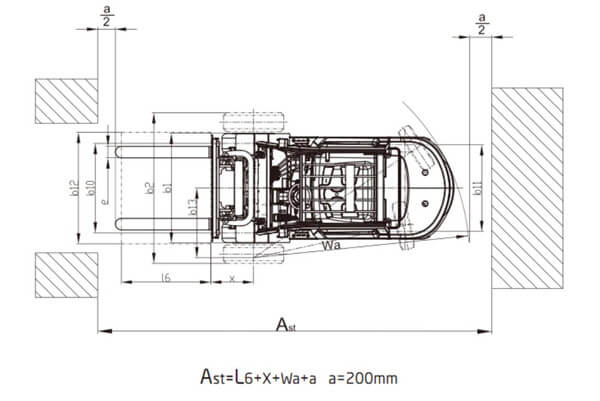

What's minimum turning radius. (Wa)

It’s about the minimum distances from the outermost and innermost sides of the forklift chassis to the turning center when a forklift is driving at a low speed without load and turning with a complete steering range.

It’s also called the minimum outer turning radius and the minimum inner turning radius respectively.

The smaller the minimum outside turning radius, the smaller the ground area required for the forklift to turn.

It means the maneuverability is much better as well.

What's minimum ground clearance. (m2)

It’s the distance from the lowest fixed point on forklift chassis to the ground without taking wheels into consideration.

It indicates the ability of the forklift to get cross the uneven ground which are with raised obstacles. The greater the minimum ground clearance, the higher passability of the forklift.

What's Wheelbase and wheel tread. (y) and (b10,b11)

The wheelbase is the horizontal distance between the centerline of the front and rear axles of the forklift.

The wheel tread is the distance between the center of the left and right wheels on the same axis. Increasing the wheelbase will increase the longitudinal stability of the forklift.

But it increases the forklift length and the minimum turning radius increased accordingly.

Increasing the wheel tread is beneficial to the lateral stability of the forklift, but it will increase the overall width of the forklift and the minimum turning radius.

What's minimum working aisle width

It’s the minimum width of the aisle that crosses at right angles for the forklift to travel back and forth.

The smaller, the better performance.

What's minimum aisle width. (Ast)

The minimum width of the passage when the forklift is in normal operation.

Maximum climbing degree with full load. (%)

It is the maximum slope the forklift can be climbed when it’s fully loaded and travelling in a low speed.

Overall dimensions. (l1, l2, b1, b2)

It’s the overall length, width and height of the forklift. If working indoors, the overhead guard height and mast lowered height are two important points to consider.

If it exceeds the door height that the forklift can not enter into the room.

heavy duty Diesel forklift

For 5.0T – 10.0T Diesel Forklift, we have chinese engine and imported engine available, EU V engine as well.

Such heavy duty forklift is widely used for rental business like lifting the empty 20′ container, carry long steel bars…etc. Its forks are extended.

We also have BIG heavy duty forklift on sale, from 12T to 32T with well known engines available. EU stage V engine available too. Comprehensive product range, greatly meet your specific requirement.

FORK FOCUS, heavy duty forklift, are highlighted with these characteristics:

- Strong structure, ensures a perfect stability

- Consistent, robust and reliable in the most challenging conditions

- Wide sight of view gives the driver a precise handling to the load and its surrounding environment.

- High level of service

- Dynamic acceleration, FASTER reversing and precision lifting and travelling.

If you don’t know how to select the right machine for you, see last chapter or contact our forklift expertise for a instant help!

FAQs for diesel forklift

Diesel forklift, as the name shows, it works with diesel engine and fuel diesel.

The diesel forklift, also called counterbalanced diesel forklift. It requires little maintenance.

Becouse of the solid structure, diesel forklift is ideal for outdoor use. With high torque of the diesel engine, it’s with fast lifting speed and mast lowering down speed. The diesel engine is robust, durable and powerful. Diesel forklift doesn’t need recharging. Can be started anytime as long as fuel inside the lift truck.

FORKFOCUS, provides large product range for diesel forklift, makes your outdoor use freely, even unever terrains.

Diesel forklift, works with diesel fuel only. You can fill in the fuel at any fuel filling station.

When comes to this question, there is no specific answer. The cost of inspection and maintenance will be different for different models. Also this operating cost relates with forklift driver habit too.

We can provide diesel forklift range from 1.5T to 42T. So just feel free to contact us for a professional solution!

Usually our diesel forklift trucks can work for 3-shift operation. However, the workload or intensity different, so the operating time varies.

YES, our diesel forklift trucks are with hydaolic tranmission.

Depending on the model you choose. We have a wide range of diesel forklift with wide range of horse power from 31w to over 100kw.

It’s very popular in EU market due to the emission standard requirement. Usually we use japanese nissan k21, k25 engine.

If your operation usually for outside driving, the forklift with combustion engines are the good choice: in diesel, gasoline, or LPG form. They provide reliable performance in almost all adverse conditions like wet environment, or uneven roads. If you want indoor operation, they can work excellently too.

LPG forklift, means the forklift can only work with LPG fuel. Also called Gas forklift, or LP gas forklift, as well as propane and butane powered forklift. Gas Forklift, is the Low-Emission Alternative To Diesel Forklift Truck.

Dual fuel forklift, means the forklift can work with gasoline or LPG.

There is the switch to change the forklift working with one of these two kinds of fuel.

Liquefied petroleum gas is superior to diesel and batteries in terms of versatility, reliability, efficiency and lower emissions.

According to relevant data, in the United States, forklifts using liquefied petroleum gas as fuel account for about 90% of the market share of IV and V forklifts.

In foreign countries, most managers also prefer liquefied petroleum gas as power instead of diesel or batteries.

For example, in foreign countries, 70% of internal combustion forklifts with a rated load of 5,000-10,000 pounds use liquefied petroleum gas.

The rated load of 10,000 or more tonnage also accounts for about 50%.

FAQs for Gas forklift

Gas forlift, means the forklift works by fuel gas.

Gas forklift is a clean alternative for a powerful forklift. It running much smoother. Also can running long distance. The same operations as diesel forklift. And it’s much easier to get the engine started, eliminates the long loading time.

Indoor or outdoors operation is available.

The fixed cost usually covers inspection, maintenance. Different driver will have different number of such cost. However, compared with diesel or electric forklift truck, LPG is relatively cost less.

We have a gas forklift range from 1.5T to 5.0T.

LPG is a gas that is compressed or pressure liquefied. Propane, butane, and LPG (liquefied petroleum gas) are among the best-known propellants.

The maximum duration of use varies and depends on the intensity of use and gas cylinder size.

A gas-powered forklift truck is powered by propellant gas that is carried with the vehicle in gas cylinders. Empty gas cylinders can be quickly and easily replaced with new ones.

Small tip: How to identify the damage degree of forklift parts

There cannot avoid part damage during forklift operation.

We need to judge the damage degree of the parts to distinguish the impact on the forklift.

So, what methods can be used to judge that?

Below are some guidance to follow:

- The impact on performance and operating mechanism:

some parts can still perform the function after being worn out, but the performance greatly reduced.

For example, the transmission gear, it can still transmit the predetermined torque and speed after being worn out, but since the gap becomes larger, that lead to the noise increases and the efficiency decreases.

What’s worse, the smoothness of the transmission is destroyed.

So under this condition, we should repair or change for a replacement according to the degree of wear.

- Impact on efficiency:

When parts are worn out, it will lead to a decrease in efficiency.

If the cylinder and other parts are worn out, it will affect the efficiency of the engine.

It should be decided to repair some parts or not according to the specific conditions of wear.

- For some general parts, even the wear degree has exceeded the tolerance, but does not exceed the sub-level matching tolerance, that it can continue to use.

- The parts cannot realize the intended function due to wear.

For example, the clutch loses the function of transmitting power, the hydraulic parts cannot reach the predetermined pressure, and the cam valve system cannot maintain the predetermined movement rule.

If the above situation occurs, it must be replaced or repaired.

- In the forklift maintenance process, the technological ability and conditions for repairing worn parts is critical to decide if change a new one or be repaired.

Side loader

We have side loader in diesel engine powered forklift on the market. Product range from 3.0T to 12.0T.

Side loader is the good tool to carry the long strip-shaped cargo like steel pipes, long timber, container…etc.

With its special side-loaded design, this forklift don’t need to make turning when working in the racking system.

It greatly fit for working in narrow space and stacking long cargo onto the shelf.

Also, we have electric type of side loader for your option.

Rough terrain forklift

Rough terrian forklift, also called off-road forklift, and they have two types of rough terrain forklift:

- 2-wheel drived or 4-wheel drived.

- 4-wheel drived also called all terrain forklift.

Engines are available:

- Yanmar 4TNE98;

- Cummins QSF;

- Kubota ( EU V engine).

You can check this post to

get close to our rough terrain forklift.

At this page about 4WD rough terrain forklift, we shared what’s the diffference between rough terrain forklift and ordinary forklift.

You will be received much information!

Telescopic forklift

It’s also called Telescopic Handler. Telescopic forklift, is a multi-purpose forklift with off-road performance and telescopic boom.

It’s can be divided into following five catagories:

- Usually lifting height is 4m-6m;

- load capacity is 1.5t-2.5t;

- 2 or 4 wheel drive;

- Diesel drive.

- Usually lifting height of 7 meters to 17 meters;

- Load capacity of 3 tons to 4 tons;

- 4-wheel all-wheel drive;

- Three steering modes (two-wheel steering, four-wheel steering, crab steering);

- With or without auxiliary support legs;

- With or Without body balance;

- Diesel drive.

- Lifting height 14m-30m;

- Load capacity 3.2t-5.0t;

- Body 400° or continuous rotation;

- 4-Wheel all-wheel drive;

- Three steering modes (two-wheel steering, four-wheel steering, crab steering);

- With auxiliary support Legs;

- Diesel driven.

- Lifting height 6m-10m,;

- Load capacity 6t-22t;

- 4-Wheel all-wheel drive;

- Three steering modes (two-wheel steering, four-wheel steering, crab steering);

- With body balance;

- Diesel drive.

- Lifting height 5m-10m;

- Load capacity 2.3-4.5t;

- 4-Wheel all-wheel drive;

- Three steering modes (two-wheel steering, four-wheel steering, crab steering);

- With or without body balance;

- Diesel drive.

Workable Attachment With Telescopic Forklift

Telescopic forklift is equipped with fork as standard.

In addition to the forks, it can be equipped with different attachments. The versatile function is achieved through thousands of attachments.

For different working conditions, different attachments are used to achieve efficient, safe and economical operations.

FORKFOCUS, can recommend suitable supporting attachments according to the customer’s operating requirements.

Applications

- Construction site

For unloading and short-distance transportation of building materials.

The building materials are directly delivered to the operating point or fed to truck cranes and tower cranes.

- Handling of various materials on the construction site and site cleaning.

Use forks and spreaders to transport block, strip, and irregular-shaped building materials;

Use hoppers to transport bulk materials and level the ground;

Use aerial work platforms for high-altitude installation;

Use glass suction cups to install curtain walls…etc.

- Industrial Enterprises

Handling various materials on rough ground.

- Agriculture and Animal Husbandry

Handling of forage bales in the pasture, shredding of forage, feeding of forage, and cleaning of manure. Transport forage, straw, etc. after packaged.

Anti-explosion forklift

SO, where you have to use explosion-proof forklift?

Explosion-proof forklifts are used in special places like factory with lot of dust, Gas station…etc.

We need to prevent any potential explosion as much as possible from these two important points:

- When work in an explosive azardous area where flammable substances have already been confirmed, we should strictly control the forklift‘s various ignition sources.

- Upon the ignition source of the forklift appropriately controlled, we need to detect the gas concentration in the environment around the forklift by the gas detection system.

- When the concentration reaches a certain ratio of its lower explosive limit, the forklift starts to alarm and finally stops automatically to achieve safety operation.

To ensure a safe forklift operation, ignition sources must be effectively controlled, including:

(1) It is necessary to eliminate the static electricity that may be generated during the forklift operational process.

Also prevent the two sides of the forklift, rear of forklift or forks from causing fire due to collision with others.

(2) Reduce the exhaust temperature of diesel engines which is up to 300-500℃ to below the specified temperature limit such as less than or equal to 135℃.

(3) The engine loses control of overspeed due to the inhalation of combustible gas or steam.

(4) When the forklift has abnormal working conditions such as extremely high water temperature, exhaust temperature, oil temperature and surface temperature.

It should be able to automatically stop the diesel engine in time.

(5) When the diesel engine burns normally or accidentally explodes, the flame will pass through the air intake system to produce back combustion.

(6) Diesel engine exhaust flames and sparks are transmitted to the surrounding atmosphere.

To sum up, explosion-proof forklift must avoid electric leakage, sparks, etc., so explosion-proof forklifts must undergo special treatment.

The difference between explosion-proof forklifts and ordinary forklifts is mainly in the circuit, which has high requirements on the circuit, especially the electric motor, such as the travelling motor, steering motor, hydraulic lifting motor.

Because the motor will generate sparks when it’s running.

There will be dangers in some special places, so special protection and isolation must be carried out, or seal it. It is fully shielded, or use AC motors.

Because AC motors have no sparks when they are working, they are relatively safe.

The connection between the wires, also has to do special treatment for protection.

Therefore, in conclusion, some dangerous places, which requires very high safety demand, such as factories with a lot of dust, Gas station…etc.

In other words, in the workshops of some electronics factories that are very sensitive to electronic interference. It’s very essential to use explosion-proof forklifts, instead of ordinary internal combustion forklifts or electric forklifts.

Please do remember, this is very eseential!

Important safety driving instructions

Forklifts belongs special equipment.

Forklift drivers must be trained by the special equipment training department before they are allowed to work.

FORK FOCUS, collected those important safety driving notice for our prospect.

- Forklift overloading is strictly prohibited;

- Forklift needs to work in the designated work area.It is not allowed to drive on the sidewalk;

- When the forklift is working, other people need to keep a sufficient distance from the forklift;

- Forklift drivers need to maintain sufficient energy;

- Use forklift warning lights properly;

- When make turning, the speed should be slow, and use the horn for safety warning;

- Better to improve forklift working environment with better light and less dust;

- The driving speed of the forklift should be reduced in order to avoid accidental injury, cargo falling, or forklift overturning;

- Don’t walk close to forklift when it’s working;

10. Avoid driving a forklift to a place with a lot of people.

How to make forklift maintenance periodically?

Daily maintenance to forklift is quite important to maintain a continuous use of the forklift.

The forklift maintenance is divided into four categories, they are:

- Daily maintenance. Needs to carry out every day

- Primary maintenance, every 50 hours of working,

- Secondary maintenance, every 200 hours of working

- Tertiary maintenance. every 600 hours of working.

Following are the maintenance steps for each kind of maintenance:

1, Daily maintenance

- Clean the dirt and soil on these places of forklift, mostly are: fork carriage, mast slide, generator, starter, battery electrode crutch, radiator, and air filter.

- Check the tightness of each part, mainly are: fork carriage support, lifting chain tightening screws, wheel screws, wheel fixing pins, brakes, and steering gear screws.

- Check the reliability and flexibility of the steering gear.

- Check for leakage, focusing on: pipe joints, oil tanks, engine oil tanks, brake pumps, lifting cylinders, tilt cylinders, water tank, water pumps, engine oil pans, torque converters, transmissions, drive axles, and main reduction gears, hydraulic steering gear, steering cylinder.

- Check tire pressure: Insufficiency should be added to the specified value to confirm that there is no air leakage. Check if the tire contact surface and sides are damaged, and whether the rim is deformed.

- Check the brake fluid and water volume: check whether the brake fluid is within the scale range, and check whether air mixed in the brake pipelines. When adding brake fluid, prevent dust and water from mixing. When adding water to the water tank, use clean tap water. If antifreeze is used, the same antifreeze should be added. When the water temperature is higher than 70℃, do not open the water tank cover. When opening the cover, put a thin cloth onto it and do not twist the water tank cover with gloves.

- Check engine oil quantity, hydraulic oil, electrolyte: Firstly, pull out the oil dipstick, clean the dipstick head, insert it and then pull it out to check whether the oil level is between the two scale lines. The oil level in the working oil tank should be between two scale lines. If too little oil, air will be mixed in the pipeline. But if too much, it will overflow from the cover. The battery electrolyte should also be between the upper and lower scale lines. If it is insufficient, add distilled water to the top line.

- Check brake pedal, micro-motion pedal, clutch pedal, hand brake inspection: Step on each pedal to check whether there is abnormal dullness or jamming. The force of the hand brake handle should be less than 300N to confirm that the hand brake is safe and reliable.

- The speakers, lights, and meters should all work normally.

- Remove the sediment from the oil filter.

- Primary maintenance

In accordance with the “daily maintenance”, and add the following work.

If one shift a day, this supposed to carry out once in a week.

- Check the cylinder pressure or vacuum degree.

- Check and adjust the valve clearance.

- Check whether the thermostat works normally.

- Check whether the multi-way shifting valve, lift cylinder, tilt cylinder, steering cylinder and gear pump work normally.

- Check whether the gear shifting function is normal.

- Check and adjust the gap between the hand/foot brake pads and the brake drum.

- Replace the oil in the oil sump and check if the crankcase ventilation pipe is intact, and clean the oil filter and diesel filter element.

- Check whether the generator and starter motor are installed firmly, whether the wiring head is clean and firm, and whether the carbon brush and commutator are worn.

- Check the tightness of the fan belt.

- Check whether the wheel is installed firmly, whether the tire pressure meets the requirements, and remove the sundries embedded in the tread.

- Due to maintenance work, some parts are disassembled. Therefore, after reassemble the parts, we should do the road test for the forklift as following:

- The braking performance should be free from deviation or snaking under different circumstance. Check when forklift drives on a steep slope, and see if the forklift can stop reliably after tighten the hand brake.

- Listen to check if there is any abnormal sound from the engine under circumstance like running under acceleration, deceleration, heavy load or no load.

- After a period of road test, check the brakes, transmission, front axle housing, and gear pump if any overheating.

- Check if the lifting speed of the fork carriage is normal or any shaking.

- Check whether the filter screen at the oil inlet of the fuel tank is blocked or damaged. Clean or replace the filter screen.

- Secondary technical maintenance

If one shift a day, that this secondary technical maintenance will be required once in a month.

In addition to maintain the items according to the primary technical maintenance, the following tasks are added:

- Clean each fuel tank, filter screen and pipeline, and check if any corrosion or cracking. Do not wipe with fiber yarn or cloth after cleaning.

- Clean the torque converter, gearbox, and check the wear condition of parts. Replace with new oil.

- Check the bearing of the drive shaft and change the direction of the universal joint cross shaft if necessary.

- Check the tightness of each part of the drive axle and see if there is any oil leakage, and dredge the air holes. Disassemble and inspect the main reducer, differential, wheel reducer, and adjust the bearing shaft. Add or replace lubricant to the gap.

- Disassemble, inspect, adjust and lubricate the front/rear wheel hubs, and perform semi-shaft shifting.

- Clean the brake. Adjust the gap between the brake drum and brake shoe friction plate.

- Clean the steering gear and check the free rotation of the steering wheel.

- Disassemble and clean the gear oil pump. Pay attention to the wear situation of gears, housings and bearings.

- Disassemble the multi-way valve. Check the gap between the valve stem and the valve body. Do not disassemble the safety valve if it is not necessary.

- Check the steering knuckle if any damage or cracks. Check the coordination of the kingpin of the steering axle and the steering knuckle. Check the wear situation of the vertical and horizontal rods and the steering arm connectors.

- Disassemble the tires, remove rust and paint on the rims. Check the inner and outer tires and cushion belts. Change positions and inflate it as required.

- Check the connection and tightness of the hand brake components. Adjust the working stroke of the hand brake lever and foot brake pedal.

- Check the battery electro-hydraulic proportion. If it does not meet the requirements, it must be removed and charged.

- Clean the water tank and oil radiator.

- Check if the fork carriage and chassis are deformed. Remove the rollers and wash it. Check each attachment if all fixed reliably. Weld it if necessary.

- Disassemble and inspect the lifting cylinder, tilt cylinder and steering cylinder, and replace the worn seals.

- Check the sensors, fuses and various switches of each instrument, and adjust it if necessary.

Fourth, the whole truck lubrication.

For a new forklift or a forklift that has stopped working for a long time, it should be lubricated within two weeks of usage.

Mainly lubricate the bearings. New oil should be used when lubricating.

Squeeze out all the old oil and lubricate it with new oil more than two times.

Please also pay attention to the following points:

- Before lubrication, the dirt on the oil cap, oil plug and nozzle should be removed to prevent the dirt from falling into the mechanism.

- When injecting lubricant with a grease gun, it should be injected until the parts of each component are combined to extrude the lubricant.

- Seasonal lubricants (oil, etc.) should be replaced in summer or winter.

FORK FOCUS EQUIPMENT

The most read:

Electric forklift, perform a critical function for indoor material handling opeartions. With the development of clean energy, it can equip with Li-ion battery as well. Productity is greatly enhanced. Electric forklift will be in higher demand than ever before.

Loading dock equipment, it works like the link between factory and transportation, and the link between transportation and storage warehouse. It’s the indispensable tool that connect two seperate parts together for a closed loop.

widely used forklift attachment

In the other page of attachment, we shared richful information guiding you buying the most suitable forklift attachment. Here we will list some of the widely used forklift attachment for

Which is the best battery for your Forklift?

Choosing the best battery for your electric forklift truck can be quite a challenge. There are a lot of factors to consider. This blog hopes to help you get more insight into

What makes a quality forklift?

There are too many articles teaching you how to buy the good quality forklift. But what does ‘good quality’ mean for a forklift? What makes the forklift a quality one? Are