Warehouse equipment supplier: FORK FOCUS CHINA,

Your requirement, our solution!

Working with FORK FOCUS, you will receive:

- Consulting selling during the entire process.

- Put your concerns at the first place.

- Work out the best plan based on your particular working condition.

- Quality product with a faster delivery available.

- Customerized color available.

- OEM available.

- Sticking with your own brand available.

- Best offer available.

There are considerably kinds of material handling equipment for warehouse operation.

Why?

It’s decided by the different working enrionments like different kind of warehouse racking system, different size of warehouse, different working intensity..etc.

Solutions always come along with needs. FORK FOCUS, has richful product to meet your different demands.

If you have no clue for this product, we suggest you reading this article in advance, in order to receive a genenal idea about it: Brief introduction about material handling equipment.

FORK FOCUS, will break this topic into pieces and share with you a definite guide.

Here we go!

Electric Pallet truck in fact is the updated version from hand pallet truck. It’s mainly used for Horizontal transportation from one place to another, and the lifting height is generally a few more than ten centimeters.

With the development of material handling, various niche market gives birth to many specific models of pallet truck.

For example, In terms of volume, the same 2t load-carrying pallet truck has a large or small volume due to light working conditions, or heavy operation conditions. We have corresponding product to solve different requirement:

- The mini type of electric pallet truck (also called economic electric pallet truck) It’s for light duty work for 4-4 hours a day.

- normal electric pallet truck. It’s for heavy duty work with big power battery to support.

According to whether the driver is standing up or not, it is divided into:

- walking type,

- standing driving type.

The left and right guardrails are also divided into large enclosures and small baffles.

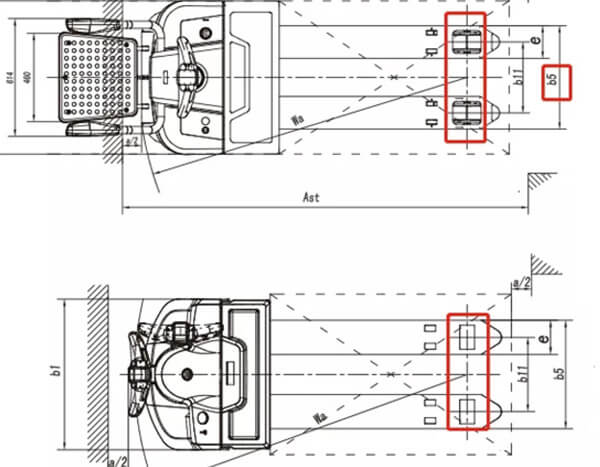

Please note that there are many specifications for the fork length and fork width.

Special customization forks can also be accepted. The load-bearing wheels in front of the forks are also divided into single wheel and double wheels, including whether the tip of the fork is equipped with a guide wheel or a guide plate, which is convenient for getting in and out of the pallet. The configurations of these different specifications are adapted to the specifications and sizes of the pallets in various places.

For example, most of the North American market is single-wheeled, while the Australian market is equipped with guide wheels because of the beam under the pallet.

In summary:

If you don’t require for a long working hours a day, that the mini model or walkie type electric pallet truck is your cost-saving solution.

If you require to work a long day that normal model or stand-up type is the ideal solution.

The electric pallet stacker is divided into two types:

As the name suggests, the former is driving and lifting controlled by electric, which is relatively labor-saving.

The latter requires manual pulling or pushing of the stacker to walk, and the lifting is by electric.

Compared with the pallet truck, the stacker has an additional lifting component (mast), which plays the stacking function. As we talked on above section, pallet truck plays the horizontal transportation. It just lifts the goods off the ground, and deliver the goods to another place.

The stacker is stacking good onto the high shelf. It’s the vertical stacking. The lifting height of the stacker truck can generally reach to 5.5m. However, due to stability reasons for some stacker trucks under light working conditions, the lifting mast generally only reach to 4.5m.

There are many models of electric stacker from different requirements.

Firstly, Look at the door frame. The conventional frame type has a channel steel mast on both sides, and some light work conditions directly use a single mast. This kind of single mast has good visibility and low material cost, but it has higher requirements for the straightness of the profile and processing. Therefore, a single-mast car is generally not made too high.

Then, according to the fork legs, it is divided into straddling type ( also called wide leg type) and insert-leg type ( also called narrow leg type). The leg-straddling style is where the two legs are separated and straddle across the tray. It’s generally used in North America.

Straddle Semi-Electric stacker

Another is to add the forward-moving function, it includes Mast-move forward and scissor reach forward. We call it reach stacker and scissor stacker separately.

reach stacker

Scissor stacker

In order to be more stable, there is a counterweight type stacker. We call it counter balance reach stacker. This greatly enhance the whole stability. It’s usually the standing type of stacker With armrest to better protect the driver.

Counter balance reach stacker

Fifth, there are other functions such as Initial lift and double stacker, which means that double pallets can be used. It doubles the efficiency. Originally two pallets had to be carried twice, but now once by double stacker.

Various configurations can be done like fork leg size, single or double wheels, guide wheels, duplex mast, triple mast..etc.

In summary:

Compared with pallet trucks that electric stackers has very rich models. It has the all options that electric pallet truck has.

In addition to this, there are various types of:

- single-mast,

- duplex mast,

- three-stage mast,

- straddle type,

- forward-moving type,

- counterweight type,

- stand-on type,

- walking type,

- double-lifting.

Most models are with high, medium and low configurations available. Greatly meet the needs of all kinds of material handling requirement.

The load capacity for reach truck is from 1.0 to 2.5 tons, and the mast can be moved forward or retracted wholly. When retracted, the width of the working aisle is generally 2.7 to 3.2 meters, and the lifting height can reach up to about 12 meters. It is often used for medium-height warehouses stacking or picking up operations.

It includes two models:

- Stand-on type;

- Sit-on type

In certain working conditions (such as the distribution center of a supermarket), the electric order picker does not need to carry the entire pallet, but selects a variety of goods according to the order to form a pallet. This process is called picking.

According to the height of the picked goods, electric order picker can be divided into:

- Low-level order picker (within 2.5 meters) ,

- Medium – high order picker (up to 10 meters).

The carrying capacity is 2.0-2.5 tons (low position), 1.0-1.2 tons (medium-high position, lifted with cab).

The electric tractor (trailer) is driven by an electric motor, and uses its towing capacity (3.0-25 tons) to pull several trolleys with cargo behind.

The main categories are: electric tractors for airport logistics, electric tractors for workshops, small electric tractors, electric three-wheel tractors, which are often used for the transportation of large quantities of goods in or between workshops, such as: the transportation of automobile manufacturing warehouses to assembly lines , Luggage transportation at the airport.

In conclusion:

There are richful products avaiable for different working conditions. Unlike internal combustion forklift, every warehouse equipment has its particular application scenarios.

You need a professional and cost-saving consult to help you work out the most practical solution for you!

Every solution works, but not every solution works for you!

So Contact us right now! FORK FOCUS is well prepared to serve you at anytime!

FORK FOCUS EQUIPMENT

The most read:

Off road forklift, range from 1.5T to 5.0T. It’s the great complementary equipment for ordinary forklift that can not work on rough terrains like muddy road. We have chinese engine and imported engines are available for different emission standards, no worry for the such engine emission requirement.

The side loader forklift, is used to carry long strip-shaped cago like steel pipes, container…etc. The lifting mast is side-positioned, unlike ordinary forklift with mast front positioned. Product range from 3.0T to 12.0T. Comprehensive solutions will be provided for you and choose the best one with less cost but best result!