One crucial part of a forklift is its battery, which provides the power needed to operate the machine.

In this article, we’ll take a detailed look at forklift batteries, including their types, uses, benefits to the operator, function, location, preservation, and safety methods.

So, whats is the forklift battery?

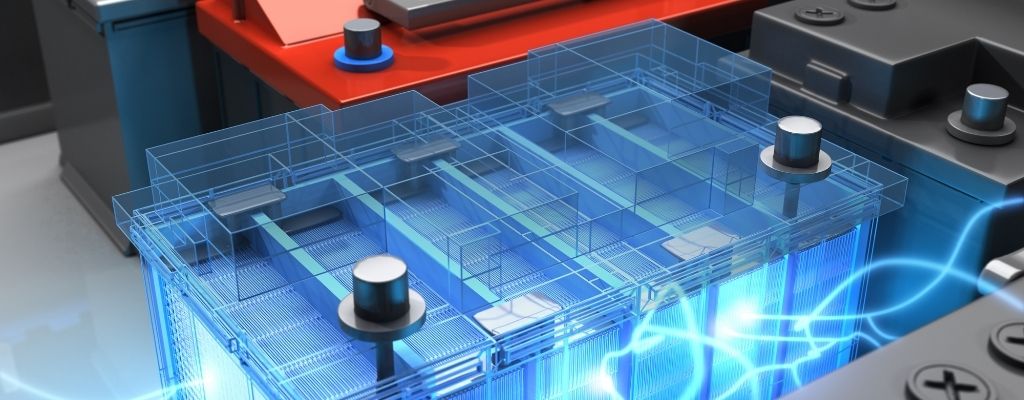

The forklift battery is a rechargeable battery that provides the electric power needed to operate an electric forklift.

It is a crucial component of an electric forklift, as it stores the energy needed to power the electric motor that drives the forklift’s movement and hydraulic systems.

Forklift batteries are typically made up of multiple cells, and their capacity is measured in ampere-hours (Ah).

Each cell in the forklift battery is made up of multiple components, including:

- Positive and Negative Electrodes: They’re made up of lead plates that are coated with lead dioxide on the positive side and lead on the negative side.

- Separator: it is a permeable layer that prevents the positive and negative electrodes from touching each other and causing a short circuit.

- Electrolyte: The electrolyte is a mixture of sulfuric acid and water that is used to conduct electricity between the positive and negative electrodes.

- Container: The container is made up of a durable plastic material that houses the electrolyte, electrodes, and separator.

- Terminals: The terminals are used to connect the battery to the forklift’s electrical system.

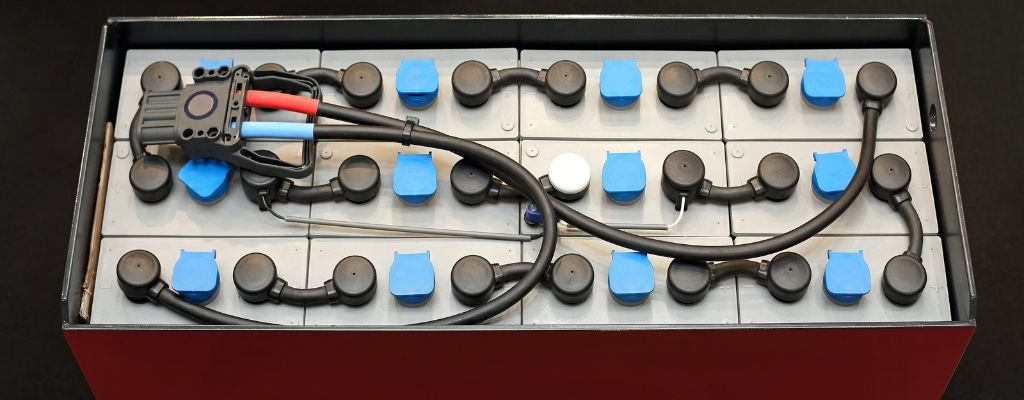

The number of cells in a forklift battery varies depending on the voltage requirements of the forklift.

Typically, a forklift battery will have 12, 18, or 24 cells, with each cell producing around 2 volts of power.

For example, a 24-volt forklift battery would have 12 cells, while a 36-volt forklift battery would have 18 cells.

What are the types of Forklift batteries?

There are several types of forklift batteries available in the market, each with its unique features and advantages.

Below are the most common types of forklift batteries used today;

- Lead-Acid Batteries: these are the most common type of forklift batteries and are suitable for all types of forklifts, including electric forklifts, reach trucks, and pallet jacks.

They are made up of lead plates, sulfuric acid, and distilled water. - Lithium-Ion Batteries: these are becoming popular due to their long life and fast charging capabilities. They’re commonly used in electric forklifts and pallet jacks.

- Gel Batteries: these batteries have a higher capacity than lead-acid batteries and are ideal for use in electric forklifts and reach trucks.

- Absorbed Glass Mat (AGM) Batteries: These batteries are maintenance-free and are suitable for use in electric forklifts and pallet jacks.

- Nickel-Iron (Ni-Fe) Batteries: they’re a more expensive option, but they are incredibly durable and can last up to 20 years with proper maintenance.

Ideally, they’re suitable for harsh environments and extreme temperatures.

What is the function and location of the Forklift Battery?

The function of a forklift battery is to provide the power needed to operate the machine.

The battery is located beneath the operator’s seat, typically at the rear of the forklift.

The battery’s location is ideal because it provides a counterbalance to the weight of the load being lifted, which improves the machine’s stability.

- Powering the forklift: its primary function is to provide power to the electric motor of the forklift, enabling it to lift and transport loads.

- Acting as a counterweight: it helps to balance the weight of the load being lifted, ensuring stability and preventing the forklift from tipping over.

- Storing energy: The battery stores energy when the forklift is not in use so that it is ready to use when needed.

As for its location, the forklift battery is typically located under the seat or in a compartment in the rear of the forklift.

This location helps to keep the weight of the battery low and centered, which improves stability and maneuverability.

The battery Charger

Basically, the charger and charging system of a forklift battery is responsible for replenishing the energy used by the battery during operation.

It is designed to provide the correct amount of electrical current to the battery to ensure a full charge while also protecting the battery from overcharging.

Where is it located?

The charger is typically located near the battery charging area and can either be a stand-alone unit or a built-in system within the forklift itself.

How about the charging Process?

The charging process for a forklift battery involves connecting the battery to the charger and selecting the appropriate charging mode.

The charging time can vary based on the battery size and the charging system used.

Are there types of forklift chargers?

Yes!

Below are the types of forklift battery chargers:

- Conventional Chargers: they’re the most basic type of forklift battery chargers, generally used for low to medium usage, and are available in different sizes, voltages, and amperages.

Conventional chargers use a manual timer to shut off the charge cycle and require monitoring by the operator. - Fast Chargers: As the name suggests, fast chargers are designed to charge the battery quickly, often within an hour or two.

They require specialized installation and must be used with compatible batteries to prevent damage. - Opportunity Chargers: they’re designed to take advantage of any opportunity to charge the forklift battery during a work shift.

They’re ideal for operations with high battery usage and limited charging facilities. - Inductive Chargers: Inductive chargers are a type of wireless charging system that eliminates the need for manual charging.

The forklift battery is charged automatically when parked over an inductive charging pad. - Automated Guided Vehicle(AGV) Chargers: the AGV charger is built into the vehicle and is designed to automatically charge the battery at predetermined intervals or when the battery reaches a certain level of charge.

It’s important to note that not all forklift batteries use the same charger. The type of charger depends on the type of battery and the specific requirements of the forklift.

Preservation and Safety methods of the forklift battery.

For a longer lifespan of the forklift battery and safe operation. Some preservation and safety methods include:

- Regular Inspection: Inspect the battery regularly for any signs of damage or corrosion.

- Ventilation: Proper ventilation is essential while operating and charging the forklift battery. It will help to reduce the buildup of hydrogen gas.

- Proper Charging: Follow the manufacturer’s guidelines for charging the battery. Overcharging can damage the battery and reduce its lifespan.

- Handling: Always wear personal protective equipment (PPE) when handling the battery, such as gloves and safety goggles. Use a battery handling tool to lift and move the battery.

- Storage: Store the battery in a cool, dry place with temperatures between 15°C to 25°C (59°F to 77°F). Keep the battery away from direct sunlight and heat sources.

- Watering: Check the water level of the battery regularly and top it up with distilled water if needed. Overfilling or underfilling the battery can cause damage.

- Disposal: Dispose of the battery according to local regulations. Lead-acid batteries are considered hazardous waste and should not be disposed of in regular trash.

Which Forklift Uses a Battery?

Electric forklifts are powered by batteries.

These forklifts are ideal for indoor use because they produce zero emissions and are quieter than gas-powered forklifts.

They are also more maneuverable and easier to control.

How Big is a Forklift Battery, and How is it Used?

The size of a forklift battery can vary depending on the size and capacity of the forklift.

Smaller forklifts may have a smaller battery, while larger forklifts will require a larger battery.

The operator will need to monitor the battery’s charge level and recharge or replace it as needed to ensure the forklift operates efficiently.

In summary, forklift batteries are an essential part of electric forklifts, providing the power needed to operate the machine.

There are several types of batteries available, including lead-acid, lithium-ion, and nickel-iron.

Proper preservation and safety methods are crucial for maintaining the battery’s longevity and safe operation.

By understanding the types, uses, benefits, function, location, preservation, and safety methods of forklift batteries, operators can ensure that their forklifts operate efficiently and safely.

Well done on learning about forklift batteries and chargers!

How can you properly maintain and care for your forklift battery to extend its lifespan?

Leave your answer in the comment section below.