Forklifts are primarily used to lift and transport heavy loads quickly and efficiently. To perform this task, forklifts are equipped with a hydraulic system that allows them to lift and lower the forks.

So, what is a hydraulic system?

Simply put, it’s a mechanism that uses pressurized fluid to generate force and motion.

In the case of forklifts, the hydraulic system is responsible for the movement of the lift cylinder, which raises and lowers the forks.

The hydraulic system is typically located at the front of the forklift, between the two front wheels.

This placement provides a stable base for the lifting mechanism and ensures that the weight of the load is evenly distributed across the front axle.

The Types of the hydraulic cylinder.

There are two types of hydraulic systems used in forklifts:

- Open-center: open-center systems use a constant flow of hydraulic fluid to power the lift and tilt functions.

- Closed-center: closed-center systems use a variable flow of fluid to power these functions.

Components of the hydraulic system

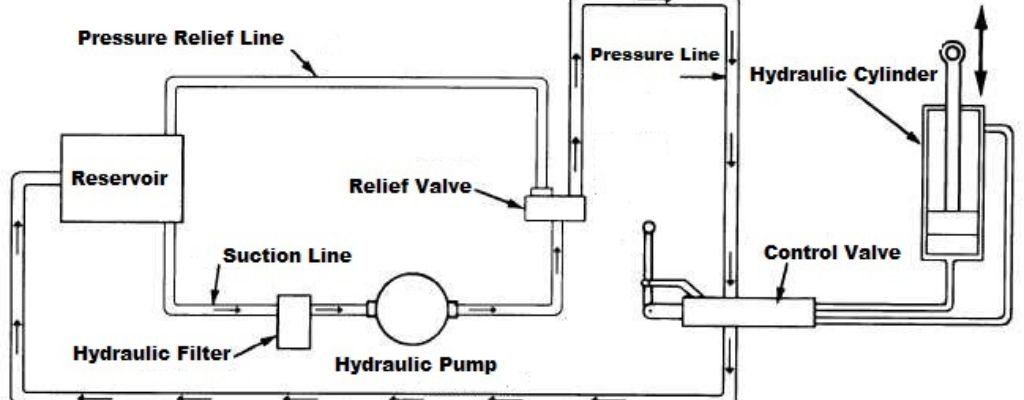

The hydraulic system consists of several components, including a pump, valve, cylinder, and fluid.

The pump draws the fluid from the reservoir and sends it through a series of pipes to the valve. The valve then directs the flow of fluid to the cylinder, which generates the force required to move the forks.

Industry Applications

The hydraulic system is used in a wide range of industries, including manufacturing, warehousing, construction, and logistics.

Any industry that requires the lifting and movement of heavy loads can benefit from the use of a forklift with a hydraulic system.

One of the primary advantages of the hydraulic system is its ability to generate high forces with relatively low power input.

This makes it ideal for lifting heavy loads.

Additionally, the system’s speed can be easily controlled by adjusting the valve, making it possible to lift loads slowly and carefully.

It’s important to note that not all forklifts use the same hydraulic system.

The specific components and design of the system may vary depending on the manufacturer and model of the forklift. However, the basic principles remain the same.

Factors to consider when ordering hydraulic system.

Buyers should take note of the following factors when ordering a hydraulic system for a forklift:

- The pressure and flow rate requirements of the system.

- The type and size of the hydraulic pump.

- The size and capacity of the hydraulic cylinders.

- The quality of the hydraulic fluid and filters.

- The compatibility of the hydraulic system with the forklift.

How to Order the hydraulic system.

Safety and maintenance of the forklift hydraulic system.

Maintaining the hydraulic system is crucial for ensuring the safe and efficient operation of the forklift.

Regular maintenance should include checking the fluid levels and quality, inspecting hoses and fittings for leaks or damage, and cleaning the system to prevent contamination.

Safety is also a crucial aspect of forklift operation. Operators should receive proper training and follow established safety protocols.

This includes wearing appropriate personal protective equipment, ensuring that the load is properly balanced and secured, and operating the forklift at a safe speed.

In conclusion, the hydraulic system is an essential component of forklifts, allowing them to lift and move heavy loads quickly and efficiently.

It’s located at the front of the forklift and consists of a pump, valve, cylinder, and fluid.

Maintenance and safety protocols are critical to ensuring safe and efficient operation. While specific components and designs may vary, the basic principles remain the same.

Well done, you’ve learned all about hydraulic systems in forklifts!

How do hydraulic systems help forklifts lift and move heavy loads?

Feel free to leave your answer in the comment section below.

#ForkliftHydraulics #HydraulicSystem #ForkliftMaintenance #HydraulicFluid #ForkliftSafety #HydraulicLeaks #ForkliftParts #HydraulicTroubleshooting