Forklifts and Forks are almost inseparable, I mean it’s practically found in the name “FORK” lift.

Well “almost” because forklift attachments are sometimes used in place of forks.

In this article, we’ve explained in detail everything you need to know about forks.

- Forklift forks, ITA, and functions.

- How many types of forklift forks are there?

- Forklift forks mounting class.

- What are the fork dimensions? How to measure?

- How are forks made?

- How to install the forks?

- What factors to consider when choosing forklift forks?

- What do I need to know before ordering forks?

- Safety and preservation.

So, What Are The Forklift Forks?

Forks are the primary component of a forklift that lifts and moves materials.

Are the forklift forks really made of steel?

Yes! But the correct answer is they’re made from high-strength alloy steel.

The forklift forks are mounted on the forklift carriage.

ITA Carriage Or Carriage?

The ITA forklift carriage is a standardized type of forklift carriage. As the forklift is attached to the carriage, both sizes must coincide (ITA carriage-ITA forks).

What Is An ITA Fork?

Usually, the ITA forks are requested. It is the most common method used to mount forks to ITA carriage. It is also called “hangers” and “hook” forks.

What Are The Functions Of The Forklift Forks?

I know whenever forklift forks are mentioned, our first thought is lifting and lowering loads such as boxes, pallets, and other materials.

Yes, we’re right. But there are a few such as; transporting loads, stacking loads, reaching high shelves, and moving materials in tight spaces among others.

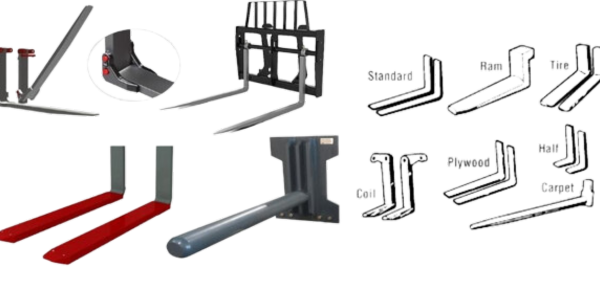

What Are The Types Of Forklift Forks?

Various types of forklift forks are available, each designed to handle specific materials. Some of these types include…

- Standard forks: these are the most commonly used type of forklift forks, and are designed for lifting and carrying a wide variety of loads.

- Block forks: these forks are designed for use with blocks and bricks, with wider and shorter designs to provide better stability when carrying these loads.

- Carpet poles are long poles that attach to the forklift and are specifically designed to lift and transport rolls of carpet or other textile materials.

- Coil rams are specialized forks that are designed to lift and transport coils of heavy metals, such as steel.

- Telescopic forks are adjustable forks that can be extended or retracted to suit various load sizes, making them versatile and ideal for use in different applications.

Folding forks, Rotating forks, side shift forks, pallet forks, and Drum handling forks among others.

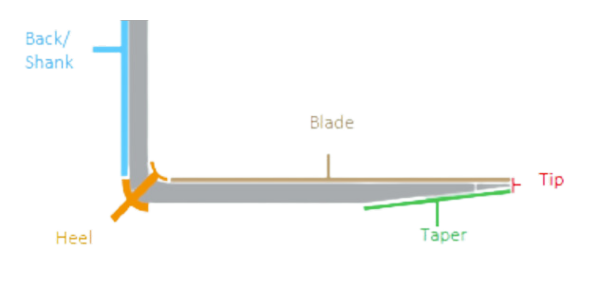

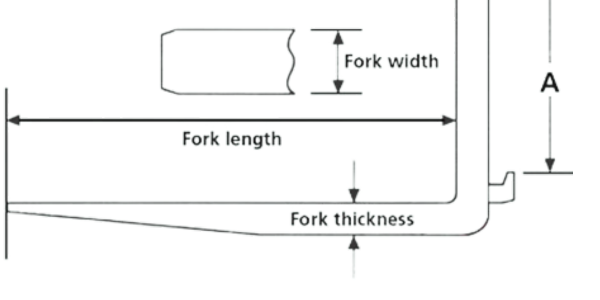

Forklift Fork Dimensions.

The dimensions of forklift forks can vary depending on the specific application and the type of forklift and the Forklift tonnage.

The main dimensions of the forks are the width, thickness, and length (WTL) of the forks.

How To Measure The Forklift Dimensions?

Length (L): Measure the length of the fork from the tip of the blade to the end of the heel. It can range from 36 inches to 96 inches or more.

Width (W): Measure by placing a tape measure or ruler across the top of the blade at its widest point. It can range from 4 inches to 8 inches or more.

Thickness (T): use a ruler or tape measure to measure the thickness of the blade at the thickest point. It can range from 1 inch to 2 inches or more.

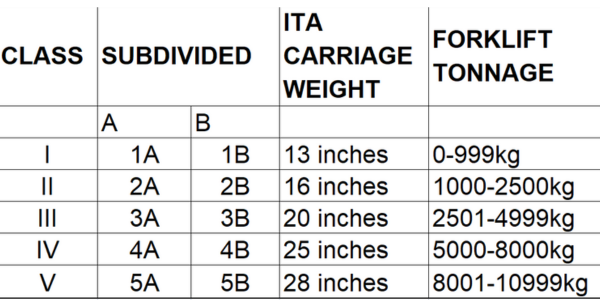

How do I classify forks?

Different classes of forklift fork mountings are classified based on their capacity and intended use i.e Class I-V. It can also be subdivided into “A” and “B”.

- Class I

- Class II

- Class III

- Class IV

- Class V

How are forklift forks made?

Forklift forks are typically made from high-strength steel and are designed to handle heavy loads. Here is an overview of how forklift forks are made:

- Cutting: The first step in making forklift forks is to cut the raw steel into the appropriate size and shape.

- Forming: The cut pieces of steel are then shaped into the desired fork shape using a press or forging machine.

- Heat treatment: Once the forks are formed, they are heat-treated to increase their strength and durability.

- Machining: After heat treatment, the forks are machined to achieve the final shape and smooth surface finish.

- Testing and inspection: They undergo rigorous inspection and testing to ensure they meet industry standards for strength, durability, and safety.

How do we mount forklift forks?

It always looks very simple whenever we see the forks mounted in front of the forklift, right? Let’s see how it is done…

- Remove any existing forks: If there are already forks attached to the forklift, they must be removed before installing the new forks.

- Align the new forks: The new forks should be properly aligned and positioned on the forklift mast.

- Secure the forks: Once the forks are in position, tighten the locking mechanism to secure them in place.

- Adjust the fork height: The height of the forks should be adjusted to match the height of the load. This can be done using the forklift’s hydraulic controls.

- Test the forks: After installation, the forks should be tested to ensure they are properly secured and aligned.

What factors to consider when choosing forklift forks?

Choosing the right forklift forks for your needs is important to ensure the safe and efficient operation of your forklift. Here are some key factors to consider:

- Fork dimensions.

- Capacity: The capacity of your forklift forks should match that of your forklift.

- Material: Consider the weight of the forks, their durability, and the type of load you’ll be handling to choose the appropriate material.

- Fork type: Choose the type of fork that is appropriate for the loads you’ll be handling and the type of forklift you have.

- Price: While it’s important to choose high-quality forks that will last, be sure to stay within your budget to avoid overspending.

What do I need to know before ordering forklift forks?

Before ordering forklift forks, here are some key things you should know:

- Forklift class: Make sure you know the forklift class and capacity.

- Forklift measurements: Measure the length, width, and thickness of the existing forks on your forklift.

- Load capacity: Determine the maximum weight of the loads you will be moving with the forklift.

- Type of material: Forklift forks can be made of different materials, including steel and aluminum.

- Mounting style: Determine the mounting style of your forklift like hook mount, pin mount, and shaft mount.

- Safety regulations: Be aware of the safety regulations and guidelines related to forklift forks.

- Supplier reputation: Choose a reputable supplier with a proven track record of providing quality forklift forks.

“The forklift class, Forklift measurement, and load capacity must be provided to the supplier when ordering forklift forks.”

Safety and preservation for forklift forks

It is important to ensure that forklift forks are maintained and operated safely to prevent accidents and prolong their lifespan. Here are some tips for the safety and preservation of forklift forks:

- Regular Inspection: Forklift forks should be inspected regularly for any cracks, bends, or signs of wear and tear.

- Proper Loading: Forklift forks should be loaded properly, with the weight of the load distributed evenly across the forks.

- Proper Use: Forklift forks should be used only for their intended purpose; Lifting and carrying.

- Maintenance: Regular maintenance of the forklift forks is essential to ensure their safety and longevity. Lubrication of the forks..etc

- Proper Storage: the forks should be stored properly when not in use. They should be kept in a dry and secure location, preferably on a rack or a pallet.

Forkfocus provides forklift forks in large quantities.

Ask for a quick quote for your forklift forks and thank me later (->)

That was quite a ride!

After reading about forklift forks, what type of forklift fork do you think would be most suitable for your specific application?

Leave your answer below in the comment section… until our next blog!